Closing the loop: how Aramco is progressing towards a circular economy

By accelerating the rollout of circular business models, we are improving our resource utilization and extending material lifecycles.

- A circular economy is one based on the idea of ‘closing the loop’, keeping products and materials in circulation instead of these resources being used once and then discarded

- In 2024, we implemented more than 300 circular economy initiatives across all business lines

- We have also undertaken several circular carbon economy initiatives designed specifically to help reduce, reuse, recycle, and remove CO2 from our operations

Every year, over 2 billion tons of municipal solid waste — more commonly known as trash — is generated around the world. Less than 20% of this waste, from unwanted food to single-use plastics, is recycled, with most of it ending up in landfill sites, which if not adequately sanitized can also contaminate the local soil, water, and air, inflicting a heavy toll on the local environment.

In the current global economy, often referred to as a ‘make, use and dispose of’ economy, raw materials are taken from the Earth to make products that are disposed of as waste after use. This process is linear. A circular economy, by contrast, ‘closes the loop’ by keeping products and materials in circulation (until they reach the end of their life-cycle) through processes like reusing, refurbishing, recycling, recovering, reducing, remanufacturing, repurposing, repairing, and rethinking. In practice, it involves reducing waste, conserving precious resources and reducing the generation of waste and greenhouse gas (GHG) emissions. Creating a circular economy is an important strategy to help support sustainability efforts, reduce pollution, and support biodiversity.

This is why, at Aramco, we have been actively applying circularity models across our operations. First established in the 1970s, the concept of the circular economy has been rapidly gathering momentum throughout the world. It is a model of production and consumption which involves using and reusing existing materials and products for as long as possible and diverting them from landfills and the environment.

The path to circularity

Despite the heightened awareness and interest in circularity over the past few years, recycling rates have declined globally from 9.1% in 2018 to 7.2% in 2023. This means that out of 100 billion tons of material extracted from the planet, only 7.2 billion tons were cycled back into the world economy in one year. There is obviously a need to shift patterns of consumption by creating policies and frameworks that incentivize the wider adoption of more-sustainable and circular practices, as well as providing support and resources to assist the transition from a linear to circular economy model.

Alongside governments, industry and the private sector can also support the transition from the current linear model to a circular economy by developing and providing circular products and services, as well as innovating in production, distribution, and recovery systems.

At Aramco, although we have fostered a culture of resource preservation for many years, we began implementing the transition to a circular economy model as a stand-alone and structured program in 2020 with the establishment of our Circular Economy Taskforce. As a first step, the Taskforce looked closely at the Company’s operations, the latest industry studies in circular economy, and the work of our peers in the field.

After reviewing best practices from around the world, the Taskforce developed Aramco’s Circular Economy Framework, which is governed by seven circular economy principles specifically tailored to our operations, services, and existing materials management practices.

Aramco’s seven principles for circularity:

- Design for the circular economy

- Build a circular supply chain

- Reduce environmental impact

- Preserve and extend resources and asset life-cycles

- Use regenerative and renewable resources

- Turn waste into resources

- Adapt innovative technologies

Gathering momentum

In 2021, Aramco commenced the roll-out of a corporate execution plan to apply these principles across the Company’s value chain. As part of institutionalizing circular economy practices, we introduced an operational excellence process to guide all departments on their journey to increase circularity. We then executed a pilot project across multiple departments that successfully implemented more than 200 circular economy initiatives.

Over the next few years, we executed a broader roll-out of the plan, introducing our seven circularity principles into our capital project guidelines and engineering standards.

Since 2024, we have been accelerating the adoption of circularity models across our operations from design and engineering to procurement, construction, and information technology. In just that year we implemented over 300 circular economy initiatives across our various value chains, with the aim of improving circularity as well as operational efficiency, safety, economic performance, and social impact. Some examples include the Drilling and Workover Circularity Program, the Procurement and Supply Chain Circular Economy Program, and the Excess Materials Management System.

This content is blocked

You need to give permission.

At Aramco, we began implementing the transition to a circular economy model in 2020.

Reduce, reuse, recycle

Preserving and extending resources and asset life-cycles enhances the utilization of equipment, and improves longevity by reusing, repairing, upgrading, and redeploying assets through recycling programs designed to recover valuable materials from waste streams.

At Aramco, we are increasingly adopting the 3Rs — reduce, reuse, and recycle — across more parts of our value chain. In our drilling operations, we reused more than 6,000 repaired drilling assets, and refurbished over 2,000 wellheads and pieces of well control equipment, in 2023 alone. We also reused 8,500 metric tons of oil country tubular goods, which are rolled metal products such as drill pipe, casing, and tubing. During the same year, we implemented the industry best practice of ‘closed-loop’ drilling in 257 wells, which involves reducing the use of chemicals in drilling operations and the reuse of drilling fluids over multiple wells. By doing this, we recycled and reused over 3.9 million barrels of drilling fluids, which helped us to reduce water consumption at these wells by 13 million barrels and reduce wastewater by 3 million barrels.

Building a circular supply chain, involves closing material loops and reducing waste creation. We implement this principle in our procurement and supply chain operations by adopting circular procurement, i.e., rethinking the need for the purchase of new assets, reusing or refurbishing existing assets, and purchasing recycled products.

To advance circular procurement, Aramco has carried out scrap recycling since 2019. In 2022, we recycled about 20,371 tons of materials such as steel scrap, plastic and steel drums, and aluminum. The following year, in 2023, we significantly increased our waste management efforts, recycling more than 85,000 tons of materials. During the same year, we began reintroducing recycled materials to local manufacturers as feedstock, which helped ease the pressure on raw material extraction.

We also carry out regular repairs on our equipment to reduce equipment waste, deploying advanced equipment repair technologies to repair a wide range of rotating and stationery industrial machinery, including turbines, compressors, pumps, heat exchangers, and power generators.

Turning waste to value

In 2022, we developed a Corporate Waste Management Strategy outlining short and long-term targets to reduce and divert waste from landfills. Our waste management strategy focuses on reducing waste generated in five areas: municipal, industrial, drilling, naturally-occurring radioactive materials (NORM), and plastic waste. We utilize a waste management hierarchy, which ranks waste management options in a manner that supports our circular economy objectives.

Aramco is always on the lookout for new ways to repurpose our industrial waste, which is generated in large amounts due to the vast scale of our operations. In 2023, we recycled 35.7% of the total generated industrial waste using technologies such as automatic crude-oil-tank cleaning to recover hydrocarbons from oily waste tank bottoms, and a radio frequency tracking technology which uses electromagnetic fields to track NORM waste from generation to storage to final disposal.

To track our waste more efficiently, we have continued to enhance our Corporate Industrial Waste Manifesting System, a specialized database of all the industrial waste circularity efforts implemented by our operating and service facilities that was first implemented in 2009 for the purpose of tracking Aramco’s industrial waste disposal, before being expanded to cover recycling efforts in 2017. This system aligns with Aramco’s Circular Economy Initiative to divert waste disposal from landfills and increase recycling and energy recovery opportunities within the Company.

Reducing environmental impact

In 2020, during the Kingdom of Saudi Arabia’s G20 presidency, the Circular Carbon Economy (CCE) approach was developed and then endorsed by G20 leaders and energy ministers, as a framework for managing carbon dioxide emissions to a level consistent with the goals of the Paris Agreement — to reduce emissions by 43% by 2030 and achieve net zero by 2050. Since adopting the Circular Carbon Economy model (CCE) in 2021, Aramco has undertaken a number of CCE initiatives to help reduce, reuse, recycle, and remove CO2 from our operations.

To reuse carbon, for example, we have the capability to capture and process up to 0.8 million tons of CO2 per year at our NGL (natural gas liquids) plant in Hawiyah. The facility, which is one of the Middle East’s largest CO2 capture and storage projects, captures CO2 and then pipes it 85 km to the Uthmaniyah field where it is injected to maintain the reservoir’s pressure and help recover more oil.

To remove carbon, we aim to advance technologies for carbon storage, and plan to store up to 14 million tons of CO2 per year by 2035. To help achieve this, we are building a Carbon Capture and Storage (CCS) hub in Jubail in the Eastern Province of Saudi Arabia. The first phase of the project is planned to be operational in 2028, with the capacity to potentially capture and sequester up to 9 million tons of CO2 per year.

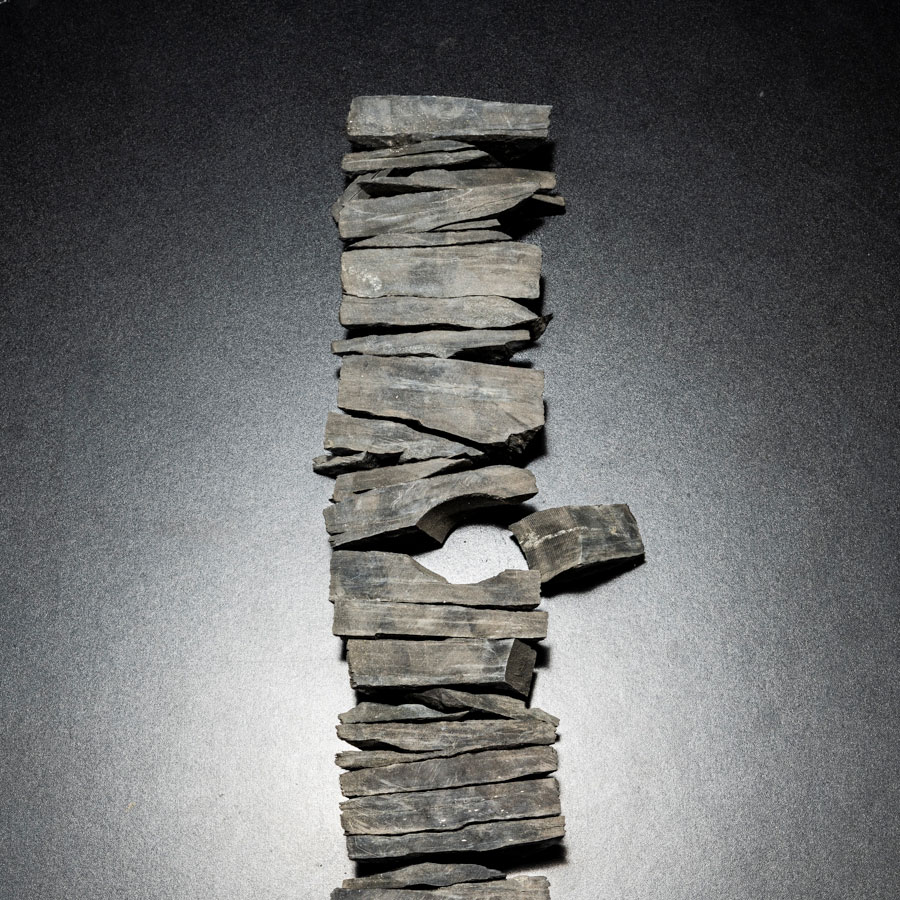

In 2023 we piloted a CO2 geological sequestration solution in partnership with the King Abdullah University of Science and Technology (KAUST), involving the injection of CO2 dissolved in water into reactive basalt formations to permanently store CO2 through carbon mineralization.

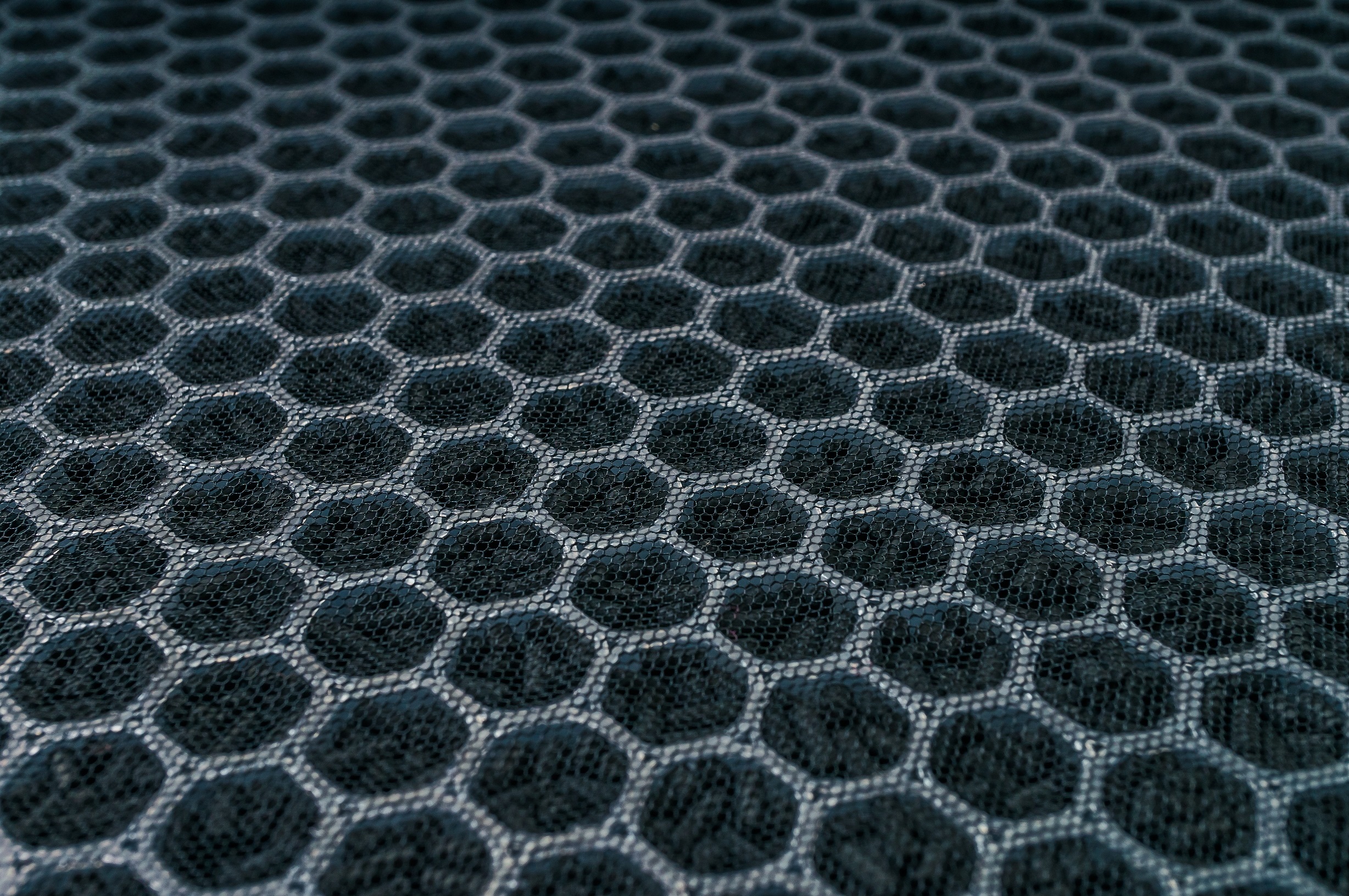

Another potential solution that we are working on to reduce CO2 emissions is direct air capture (DAC). DAC technology is designed to remove CO2 from the atmosphere, which can then be utilized in value-added products (including lower-carbon fuels) or sent for storage in underground formations. Although the technology has not yet reached full commercial deployment, several pilot-scale DAC plants have been commissioned globally. In March 2025, in collaboration with Siemens Energy, we launched the Kingdom’s first CO2 Direct Air Capture (DAC) test unit, in Dhahran. This project has the capacity to capture up to 12 tons of CO2 per year.

To help reduce our environmental impact, we are also investing in renewable energy sources — one of our circular carbon economy principles which has a key role to play in the circular economy transition. We have set ourselves an ambition to invest in up to 12 GW of solar and wind energy by 2030.

To put this into action, in 2021, we invested in a 30% stake in the Sudair Solar Photovoltaic Independent Power Plant through our subsidiary the Saudi Aramco Power Company (SAPCO). In 2024, the solar plant began commercial operations and reached a full capacity of 1.5 gigawatt (GW) of solar power generation. We continued to make progress towards our renewables target in the third quarter of 2024 by reaching a financial close for stakes in three additional solar photovoltaic projects, with an anticipated combined capacity of 5.5 GW.

We are also exploring geothermal energy opportunities in Saudi Arabia, where geothermal energy resources are available, particularly along the Red Sea, due to high heat-flow from deep in the Earth. Geothermal energy can be used for district heating and cooling, water desalination, and electricity generation.

Innovation and circularity

Transitioning to a circular economy requires a well-functioning innovation ecosystem. This is why creating and adopting innovative technologies is a key focus area of our circularity efforts.

In 2021, we developed an award-wining Zero-Liquid Discharge Technology that removes contaminants and salts from oil and gas field-generated water, allowing us to recycle and reuse treated water to inject into the reservoir fracking operations. This technology won the Best Water Management Technology Award at the 2022 World Oil Awards.

Our focus of sustainability-related innovation has only increased over the past few years, with our dedicated R&D investment in 2023, amounting to approximately $540 million, which was more than half of our total R&D spend for that year. This investment encompassed sustainability-focused solutions aimed at improving our operational energy efficiency, and, of course, enhancing company circularity.

In partnership with SABIC, the Saudi-founded global petrochemicals company, we are developing technology to recycle plastic waste by converting it into circular polymers. This process allows the use of difficult-to-recycle used plastics, which would otherwise be destined for incineration or landfill. In 2023, we achieved a milestone in the project by successfully converting oil derived from plastic waste to produce the MENA region’s first ISCC certified circular polymers, a substance that can benefit a wide range of industries including packaging, logistics and distribution, and consumer goods. In 2024, we successfully used these circular polymers to upgrade three ‘Shoot for the Future’ community basketball courts in Beijing, in partnership with the Chinese Basketball Association (CBA).

Working towards a ‘no-waste’ economy

A circular economy is underpinned by a system of ‘no-waste’: today’s products are tomorrow’s resources. However, on a global level, the roadmap for zero-waste is a gradual process guided by forward-looking strategy, which requires governments, companies and individuals to collectively act to reduce waste generation.

At Aramco, we strive to make our resources more dependable, more-sustainable, and more useful. As we continue accelerating the adoption of circularity across our operations, it is helping us enhance operations, reduce our waste, stimulate innovation, and, importantly, conserve our natural resources by ‘closing the loop’ — a ‘win’ for both the business and our environment.

- This article was amended on 2 September 2025 to reflect the revised operational date for phase one of the Carbon Capture and Storage Hub in Jubail. The CCS Hub was originally scheduled to start operations in 2027, but this has been revised to 2028.

More from Elements

The material in this article is intended to be for general informational purposes only, and readers should not place undue reliance on the statements or opinions therein. Any information provided speaks only as of the date this content was published and Saudi Aramco undertakes no obligation to correct, update, or revise any statements or opinions made in or implied by this article.