Meet Aramco's divers

We shine a spotlight on our divers to showcase their expertise in keeping our offshore operations running smoothly.

- Aramco’s divers play an important role in maintaining our offshore assets

- They perform maintenance and repair operations that include inspecting 650 kilometers of subsea pipelines and 72 offshore platforms annually

- Divers require extensive training and international certifications, which prepare them for the underwater challenges they may face, including zero visibility and strong currents

When most people think about oil and gas operations, they picture towering rigs, long pipelines, and high-tech control rooms. But a lot of the real action happens where few ever go — beneath the waves.

It’s in this challenging underwater environment where Aramco’s specialized diving teams operate, working in conditions that demand exceptional skill and precision. Their services are essential not only to our marine operations, but to the entire Company. Our divers are our eyes, ears, and certainly hands, beneath the sea, where they are dispatched to perform detailed work, from inspecting subsea pipelines to maintaining offshore assets — including platforms, vessels, and barges.

Unlike recreational divers who take up the sport to enjoy the underwater beauty and peace, commercial divers (who are the only type of divers we employ) are dedicated to work. This distinction becomes clear as we turn to meet four of Aramco’s diving specialists, each with a different area of expertise — from shallow water air diving to deep-sea saturation diving. They share what it’s really like to do their jobs, the challenges they face, the training that keeps them safe, and the stories that stay with them long after they surface.

Aiman Bohlaiga, Air Inspection Diver

Aiman Bohlaiga takes pride in being Aramco’s first Saudi commercial diver. Born in the small town of Hofuf in Saudi Arabia’s Eastern Province, Bohlaiga grew up in the coastal city of Al-Khobar, where he was fascinated by the water from a very young age and dreamed of exploring the world beneath the sea one day.

When Bohlaiga told his family about his interest in pursuing diving as a profession, they were concerned about the challenges and risks involved. But he was determined and went on to pursue a career in commercial diving to turn his childhood dream into reality. After completing his training and certifications, Bohlaiga joined Aramco in 2001 as a construction diver and, over the years, his role evolved into a specialized subsea inspection professional.

Bohlaiga says diving is a 24-hour operation conducted through rotational shifts; it doesn’t stop.

He describes his daily subsea inspection work as a delicate dance with technology and nature. Each dive starts with a supervisor’s pre-dive briefing covering the dive plan (a detailed outline of the dive’s purpose and route), safety protocols (standard operating procedures designed to prevent accidents), and the tasks for the day. Bohlaiga then suits up, dons his diving helmet, which weighs approximately 15 kilograms, and submerges to begin the inspection, usually at moderate depths that range between 10 and 50 meters. Not only does the diving helmet offer protection, it is also fitted with a camera and a two-way communication system. The helmet is connected to an ‘umbilical cord’, resembling a thick yellow rope that supplies air, transmits communications, and serves as a lifeline to the surface, similar to the function of an umbilical cord in a mother’s womb. As Bohlaiga navigates pipelines and platforms, on the surface, a supervisor monitors the process closely and communicates directly with him via radio.

The diving helmet is connected to an ‘umbilical cord’.

On any given day, his work includes inspecting an offshore platform, clearing the way for a rig barge, or repairing an underwater pipeline. This means using heavy equipment like jackhammers, drills, welding and cutting torches, and a host of other equipment — all of it underwater.

When Bohlaiga reaches the depth at which he will be working, his body — like all divers — comes under a certain amount of pressure. The deeper he goes, the more pressure he experiences. As he begins to surface, he must make ‘decompression stops’ along the way; otherwise, it can cause decompression sickness, commonly referred to as ‘the bends,’ which can cause joint pain, dizziness, trouble breathing, or even serious injury.

Each dive, Bohlaiga notes, is a calculated risk, which is why our divers use U.S. Navy decompression tables — publicly available standardized depth and time charts adopted by Aramco to determine how long a diver can stay at certain depths, along with required decompression times.

The job isn't just technical — it's psychological, Bohlaiga says. "This is because you never trust the sea," he explains, recalling his early night dives when being alone in the pitch-dark sea with zero visibility tested his resolve.

Beyond the technical challenges, he also highlights the human element of diving operations. Offshore work means extended periods away from family, with loved ones anxiously awaiting each safe return. "Every day is a challenge — for us and our families," he admits. Bohlaiga sees his journey as more than a career — it's a daily contribution to keeping the Company’s operations running.

"I'm not just a diver, I am part of a team that works to ensure the safe and responsible operation of our energy infrastructure.”

Aiman Bohlaiga, Air Inspection Diver

Craig Chisholm, Air Diving Supervisor

When Craig Chisholm talks about diving, his eyes light up. With 36 years of diving experience, the diving supervisor knows exactly what happens beneath the waves.

"The offshore activity that you see on the surface of the sea is just the tip of the iceberg," he says with a knowing smile. "Underneath, there's a complex network of pipelines and structures that keep the oil flowing,” he adds.

Some of these pipelines have been in place for decades, and as part of our efforts toward safety, we conduct regular inspections, maintenance, and repairs to support the integrity and reliability of our pipelines.

Only divers can do this job, Chisholm says, adding that each year the diving team runs a proactive campaign to inspect 650 kilometers of subsea pipelines in addition to 72 offshore platforms — helping ensure the continued safe and reliable operations of our assets.

As Aramco continues developing its offshore fields, our divers work ambitiously to support the safe installation of new infrastructure, alongside their critical work in maintaining existing assets, Chisholm explains.

"We're not just fixing pipes; we play a role in supporting the safe and responsible operation of offshore facilities, from installation to maintenance and repair,” he adds.

Divers also support offshore construction by installing and maintaining subsea production systems, such as pipelines, umbilicals, floating structures, and offshore platforms. They also help align underwater pipelines, which is an important task because, unless the pipelines are connected to subsea structures, oil and gas do not flow through them safely.

Chisholm notes that the job demands extraordinary expertise, for which divers must undergo specialized training and obtain certifications from international bodies such as the International Marine Contractors Association (IMCA). Continuous safety, medical, and technical training is also mandatory to maintain competency, he says, quickly adding that safety is paramount for Aramco’s divers who must navigate challenges like decompression risks, strong currents, and zero-visibility conditions.

"One wrong move can be catastrophic," he warns. "This is why we're constantly monitoring depth, current speed, and each diver's condition."

One of Chisholm’s most memorable diving experiences involved a project with zero visibility. "We practiced working blindfolded on the ship for two weeks before the dive," he recalls. "I even told the team to practice shaving their beards in the dark. Everyone thought I was crazy — until we completed the job perfectly,” he says with a laugh.

"The offshore activity that you see on the surface of the sea is just the tip of the iceberg. Underneath, there's a complex network of pipelines and structures that keep the oil flowing.”

Craig Chisholm, Air Diving Supervisor

Malcolm Cubin, Saturation Diver

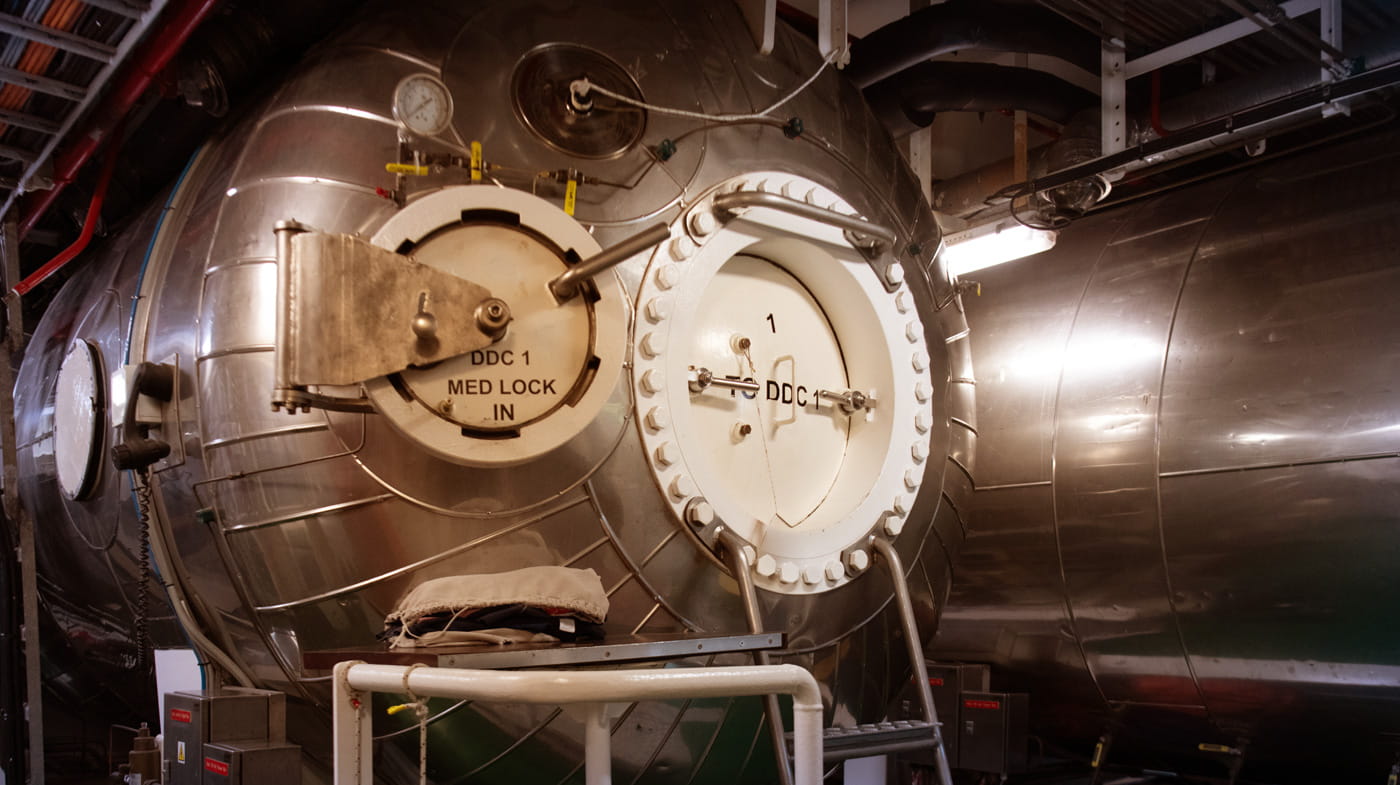

As a saturation diver, Malcolm Cubin navigates extreme underwater environments. Saturation diving is a complex form of diving where divers live in pressurized underwater chambers for up to 28 days and work at significant ocean depths, typically beyond 50 meters below sea level.

Cubin’s 28 years of diving experience, including 11 years with Aramco, mean the subsea is almost his second home.

He explains that a typical saturation dive involves intricate procedures: living for several days in pressurized underwater chambers (sealed rooms filled with air at high pressure), and being ‘blown down’ or gradually compressed from the chambers to the seabed. This is done using a ‘diving bell’ — a specialized chamber used to transport divers to and from underwater work sites. Think of saturation diving as an underwater space mission, where every movement is calculated and every piece of equipment could mean the difference between success and catastrophe. Typically, three saturation divers work 8-hour shifts, performing complex tasks such as pipeline repairs, structural inspections, and maintenance of offshore platforms. Cubin notes that the working depth in Saudi Arabia’s Eastern region, where our saturation divers operate, usually ranges between 30 and 65 meters, with divers taking turns as the rescue or backup diver while others work on the seabed.

He adds that the job demands high psychological resilience. Divers must manage tight living spaces, complex equipment, and potential emergency scenarios.

Saturation divers operate underwater from a ‘diving bell’ which is a pressurized chamber.

“You’ve got to have the right mindset with saturation diving because if anything goes wrong, you must remain calm; you can’t just drop your weights and head to the surface like a scuba diver,” Cubin says.

The challenges are distinct and demanding, he explains, adding that losing contact with the diving bell or becoming entangled in the umbilical can be life-threatening. "Your only safe haven is that diving bell," he notes. "There is nowhere else you can go if it goes wrong." The cold is another constant challenge, with divers relying on hot-water suits fed through their umbilical cords. If that system fails, the temperature change is sudden and dangerous.

Cubin also explains how modern technology has transformed the profession. Divers now enjoy communication capabilities unimaginable decades ago, he says, which allows them to connect with families during extended underwater missions. For Cubin, the underwater world is a canvas of scientific exploration and engineering marvel. "It's like working in a silent, alien environment," he reflects. “I love the water, and there’s something so calming about the quiet, focused work environment with marine life around you.”

"Your only safe haven is that diving bell," he notes. "There is nowhere else you can go if it goes wrong."

Malcolm Cubin, Saturation Diver

Sultan Ahmadi, Air Construction Diver

Sultan Al Ahmadi’s passion for the ocean was sparked while studying marine sciences at King Abdulaziz University and has since evolved into a career. Ahmadi is a Saudi diver with over 23 years of professional diving experience, including 10 years at Aramco.

“When you're underwater, you have no room for error,” he explains. “You have to work with a primary plan and at least two backup plans because there are limitations on time and visibility, and the pressure — both literal and mental — is immense.”

Al Ahmadi’s emphasis on contingency planning reflects the high-stakes nature of professional diving, where quick decision-making and focus are necessary.

Al Ahmadi holds multiple commercial diving certifications accredited by the International Marine Contractors Association (IMCA), including an inspection certification from France, a Diving Medical Technician (DMT) certification from South Africa, and a Trainee Diving Supervisor qualification from Singapore. Throughout his career, Al Ahmadi has taken pride in contributing to major inspection campaigns. One memorable highlight came during a routine inspection in 2013, when his team identified an underwater valve requiring maintenance and promptly acted to address the issue — an intervention that helped prevent a potential disruption to offshore operations. His efforts were formally recognized by the Company, as were his contributions to inspection campaigns in Yanbu and pipeline assessments across the Kingdom.

In addition to his field expertise, Al Ahmadi is also a trained operator of the Shallow Water Inspection and Monitoring Robot (SWIM-R), a device with advanced technology developed by Aramco that assists divers with visual inspections, marine life cleaning, and voltage measurements in shallow waters. Divers can operate the device remotely from onboard the dive vessel.

Each year, the divers inspect hundreds of kilometers of subsea pipelines.

But perhaps one of Al Ahmadi’s most meaningful contributions to the field of diving lies in mentoring the next generation of divers. “I’m proud to support new divers as they enter the field,” he says. “Becoming a professional diver isn’t something that happens overnight — it takes years of rigorous training, certifications, and continuous learning.”

For Al Ahmadi, the sea is both a workplace and a lifelong passion. His journey — from student to certified diver, technician, and mentor — highlights Aramco’s broader commitment to developing local talent in specialized fields.

“When you're underwater, you have no room for error,” he explains. “You have to work with a primary plan and at least two backup plans because there are limitations on time and visibility, and the pressure — both literal and mental — is immense.”

Sultan Ahmadi, Air Construction Diver

More from Elements

The material in this article is intended to be for general informational purposes only, and readers should not place undue reliance on the statements or opinions therein. Any information provided speaks only as of the date this content was published and Saudi Aramco undertakes no obligation to correct, update, or revise any statements or opinions made in or implied by this article.